Of all the industries, the manufacturing sector has been lagging behind in adopting digital technologies such as artificial intelligence, robots, machine learning, nanotechnology, etc. Industry 4.0 is one such technological advancement that has completely changed the game for manufacturing as it provides the vision for smart and interconnected plants where all the tools and equipment are connected using a common platform and are capable of making intelligent decisions on their own.

The explosion of data from various connected platforms has made it imperative for various enterprises to rapidly evolve from a physical to a digital world. As the manufacturing industry moves to mass customization from mass production, it needs to ensure to walk on the path of smart manufacturing by digitizing the different components within its supply chain and operations.

Digital transformation allows factories to create a fully networked, integrated and connected environment with access to real time manufacturing data to yield high product design, productivity gains, and reduced waste and operational expenses.

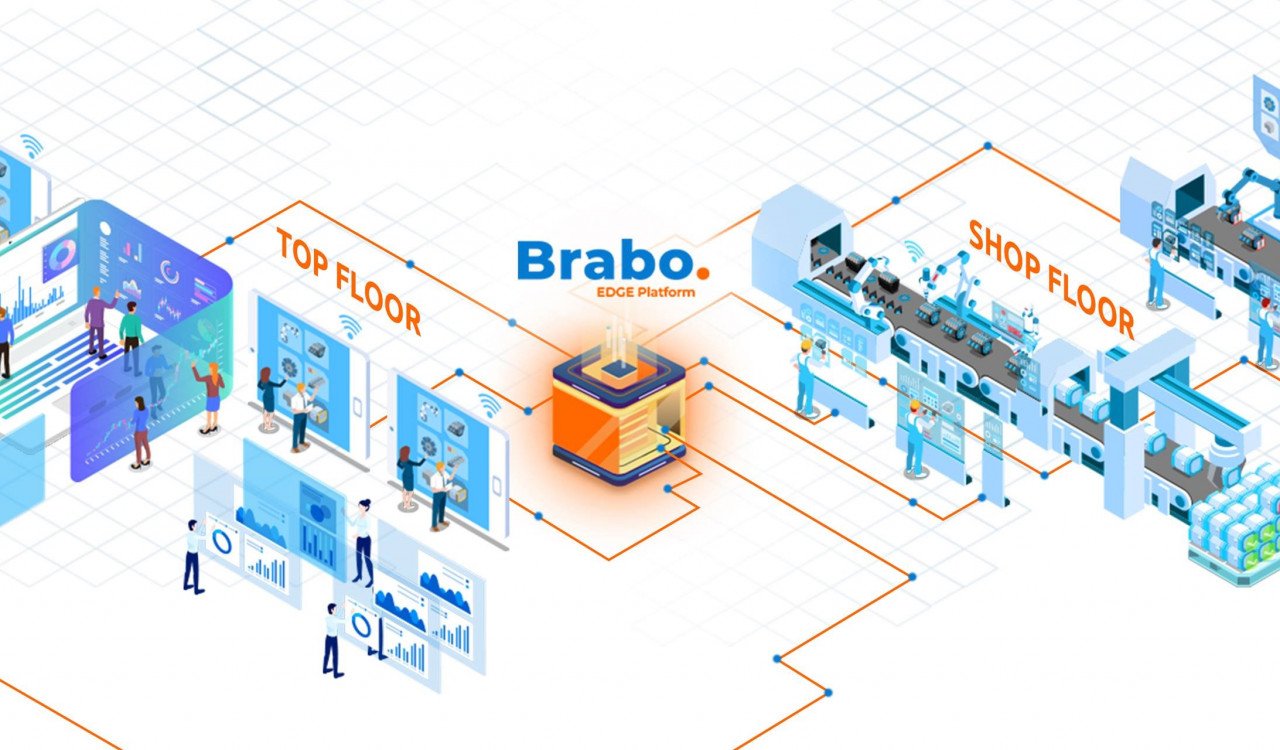

Solulever, a Dutch Technology Startup is based on the principles of Industry 4.0 and delivers top industrial connectivity platforms to help you in taking up digital transformation of your plant. One of its key products, Brabo Edge platform®, enables holistic and flexible digitization of the different manufacturing factories. It is a manufacturing connectivity and intelligence platform that allows easy and quick access to production data, operational data, and quality data using big data analytics. The Industry 4.0 platform overcomes some of the most common entry barriers faced by the manufacturers which include adoption barriers, increased capital expenditure, data connectivity, and many more. Brabo is a platform of platforms which allows seamless connectivity to different tools and equipment at the shop floor, through which it performs data mashups which is available to the development teams on a real time basis.

Based on a microservices architecture architecture, Brabo relies on an open source environment that gives the manufacturers the flexibility to opt for their desired hardware and software solutions only, that saves them a fortune from investing into yet another cloud heavy solutions. The platform is designed in a manner that it can easily communicate with the existing platforms at the plant, without having to bring in another mediator. The data and communication is normalized using Brabo which makes it easy for the developers to perform real time calculations at a fast pace.

Integrating the latest Industry 4.0 platforms, manufacturing sites can reduce their downtime and operational costs considerably. As the machines get smarter, occurrences of predictive maintenance are reduced, resulting in higher quality output. Optimizing the supply chain and using the resources smartly lead to higher plant productivity and cost efficiency, allowing manufacturers more room for innovation. Take your manufacturing business a step ahead with Solulever and digitize your shop floor to have more flexibility in the manufacturing processes to respond better to your customer demands. With smart manufacturing, you are not simply a mass producer, but an innovator for every customer’s individual needs.