Advanced Product Quality Planning (APQP) is widely adopted, yet poorly implemented. Many organizations claim to “use APQP” while still suffering from late design changes, weak risk mitigation, PPAP rejections, and costly launch issues. The gap is not intent—it is execution.

Successful APQP implementation requires more than templates or compliance checklists. It requires a structured execution system, supported by proper training, tools, and cross-functional alignment.

Organizations that implement APQP effectively typically rely on comprehensive, execution-focused APQP training—such as Excedify’s APQP course

https://www.excedify.com/courses/apqp-training

which is designed around real project workflows rather than isolated documentation.

Why APQP Implementations Fail

Most APQP failures are systemic and repeatable:

- APQP treated as documentation instead of decision-making

- FMEA created too late to influence design or process choices

- Weak linkage between DFMEA, PFMEA, Control Plans, and PPAP

- No ownership or cross-functional accountability

- Lack of data-driven validation (MSA, SPC)

These issues are not caused by APQP itself, but by how it is implemented.

APQP as an Execution System

APQP should be implemented as a management framework that governs:

- When decisions are made

- How risks are identified and reduced

- How readiness is validated

- How learning feeds future programs

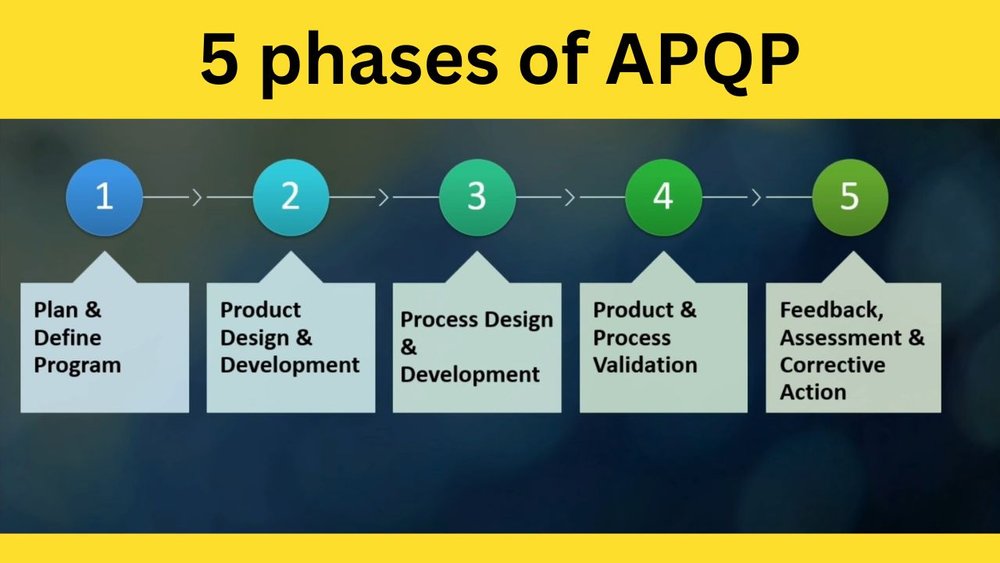

This requires consistent structure across all five APQP phases.

Step-by-Step APQP Implementation

1. Plan and Define Program

Start with clear customer requirements, feasibility assessments, and risk assumptions. APQP ownership must be defined, and cross-functional teams aligned from the beginning.

2. Product Design and Development

DFMEA must actively influence design decisions—not just document risks. Design reviews, verification plans, and requirement traceability are critical.

3. Process Design and Development

PFMEA, Process Flow Diagrams, and Control Plans must be created together. Controls should directly mitigate prioritized risks, not exist as generic checklists.

4. Product and Process Validation

Validation must be evidence-based. PPAP, MSA, SPC, and capability studies confirm that the process can consistently meet requirements—not just once, but repeatedly.

5. Feedback and Continuous Improvement

Lessons learned, performance data, and corrective actions must feed back into future APQP cycles to prevent repeat failures.

The Role of Training and Tools

APQP cannot be implemented effectively through theory alone. Teams need:

- Clear understanding of why each APQP activity exists

- Practical examples aligned with real projects

- Interactive tools to execute, not just document

Excedify’s APQP training

combines structured instruction with interactive FMEA templates, PPAP checklists, and MSA/SPC calculators, enabling teams to apply APQP decisions with real data and traceability.

This integration of training and execution tools is a key differentiator between superficial APQP adoption and true implementation maturity.

Measuring APQP Implementation Success

Effective APQP implementation results in:

- Earlier risk detection

- Fewer late engineering changes

- Higher PPAP approval rates

- More predictable launches

- Lower cost of poor quality

If these outcomes are not improving, APQP is likely being followed in form—but not in function.

Conclusion

APQP works when it is implemented as a structured execution system, supported by proper training and practical tools. Organizations that treat APQP as paperwork will continue to struggle with the same quality problems.

For teams seeking to implement APQP correctly—across industries and project types—Excedify’s APQP training

provides a comprehensive, execution-focused foundation for sustainable quality planning.